Thermal oil ovens for bakery industry

Due to its exceptional energy efficiency, thermal oil is a valued medium for heating production ovens in baking and confectionery industry.

In the area of baking temperatures it is found in the liquid state and normal air pressure. As a medium, the oil is conducted throughout the system and the temperature is controlled using pumps, mixing valves and sensors controlled by a central computer system. Thus, it is possible to build baking ovens with large baking surface on a relatively small floor plan.

In thermal oil ovens, baking temperatures of up to 280oC can be achieved easily, with only a 15 K temperature difference required for energy transfer.

The heat transfer to the products is therefore extremely gentle, drying out during baking is minimal, the crust remains juicy, and the the products are fresh for longer periods of time.

Principle of operation

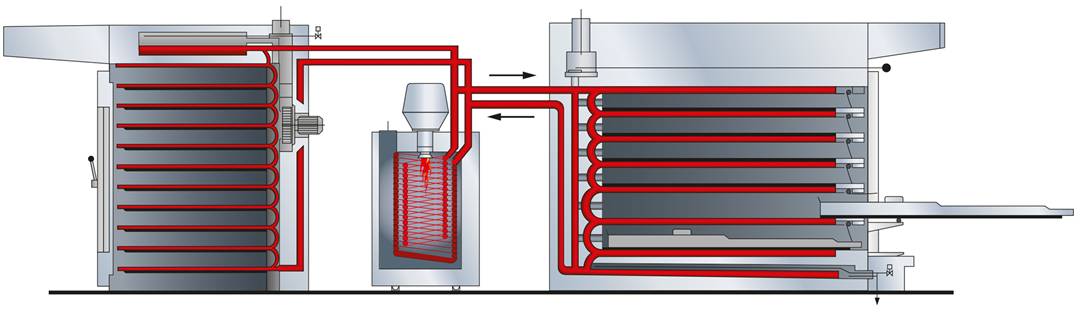

The thermal oil oven system is best compared to the central heating at home, except that with ovens, instead of water, a special, temperature-resistant oil circulates through the system. The oil is heated in a separate boiler for central heating, from which the water pumps push it through the pipes to the heating plates in the oven, which are comparable to radiators.

The heat for baking is transferred from the radiating heating plates. From the oven, the oil is returned to the heating boiler for reheating.

The oil supply between the heating central unit and the oven is called the primary piping, and the direct supply to the oven is the secondary piping. A group of radiators in the oven connected to the same secondary circuit operates at the same temperature. In practice, this means that a single oven can have several temperature modes.

Choosing the appropriate thermal oil oven system depends on the specific production requirements

Static thermal oil baking ovens, are available in versions with up to 12 decks and baking surfaces of up to 60 m2 per oven. For loading and unloading such large ovens we use automatic loading/unloading devices. A single device can handle multiple ovens and allows flexible operation with minimal physical effort.

Thermo-roll, static trolley ovens, are suitable for baking products on baking trays, and their handling is just as easy as with rotary ovens.

Baking takes place using radiated heat from the radiators, which are built into the oven in the form of oven decks. Trolleys for using baking trays in the oven are designed so that we simply insert them in between: one radiator is located just below the baking tray, and the other at a certain height above the product.

Thermo-roll ovens with stone slabs are also interesting. We fill them using special setters, so that the products are baked directly on the stone. Baking effect is similar to baking in multi-deck ovens, where heat is transferred by radiating hot surfaces and direct contact of the product with the hot stone floor.

Thermal oil tunnel ovens, for a fully automated baking

1_Single-deck tunnel ovens are used for baking large batches directly from the production line. They are designed according to the requirements of the production line, in accordance with the dimensions of the product and the required method of baking.

It is possible to have baking surfaces of up to 240 m2, with conveyor lengths of up to 60 m. The use of space is higher due to the exceptional lengths of ovens, however the exceptional heat capacity of the thermal oil exceeds its own.

2_Multi-deck tunnel ovens, are similar to tunnel ovens in terms of product transport, but significantly differ in terms of operation method and flexibility of use.

Using them, we achieve the largest baking areas on a small floor plan. Versions with up to twelve oven decks and up to 350 m2 of baking surface and more are possible.

Each deck is an independent construction unit and in fact an independent oven, with its own baking mode and independent conveyor drive. The oven decks are well insulated and mounted one above the other so that they extend freely in terms of temperature and do not affect one another.

Central heating unit

Central heating unit is an independent unit separate from the oven, which supplies the oven with a hot, liquid heating medium. It is installed in a space separate from the oven, and the advantages of such an arrangement are the following:

- the ovens do not have a boiler furnace, there is no noise in the bakery due to burners

- one burner services one central heating unit, and thereby several ovens, meaning there are less burners in the bakery

- burners in a separate place is not exposed to harmful factors (flour, humidity, high temperatures), which favorably affects the reliability of operation and service life.

Central heating units are heated using conventional fuels (gas, fuel oil, biomass). Different capacities are available so that for each installation we are able to choose a model that optimally meets the energy needs of the connected furnaces. It is also possible to plan subsequent increase in capacity of the central heating unit in the first phase, once we need additional baking space.

Central heating unit is designed so that its current capacity is based on the current energy needs of the connected ovens. For example, if only one of the connected ovens is running, the central heating unit will operate with the capacity needed to meet the energy needs of the oven that is turned on. Thus, the oil within the system is not unnecessarily heated, which contributes to a longer service life and lower energy consumption.