In-store baking

Baking in front of the eyes of consumers is nowadays a standard that cannot be overlooked when planning a new grocery store or restaurant.

The smell of freshly baked bread is a factor that evokes a pleasant homely atmosphere in any environment and entices customers.

Before introducing the in-store baking into a shop, restaurant or a hotel, shopping center or a small kiosk at a sports hall, it is advisable to first choose a concept that will fit well into your working environment.

We should never disappoint our customers, products should be available all day and every day equally fresh and of the same quality. It is very important that we constantly update our offer, follow local customs, seasonal offer, trends, events, even fashion, if you like.

A small bakery or pastry shop is already a magnet for customers, even without an oven on the counter because it always smells of fresh bread in the area. With a small oven in the store itself or with a glass wall through which customers can see the bakers at work, we are able to create a truly magic in any bakery.

Baking pizza in the shop itself also belongs to this category. It is necessary to choose the right kind of oven, that meets the requirements of the product and your method of work: a wood-burning oven for a rustic effect or a modern electric one.

Shop and gastronomy facilities, where organization of own daily production of bread, pastry and similar products is not possible or maybe does not pay off, are another story. For these cases, use of ready-to-bake products, prepared in professional bakeries, makes sense. If manufacturer’s instructions regarding the handling with the products are consistently followed, the success is guaranteed.

1. Parbaked products

The products are partially or completely baked at the bakery, where they are rapidly frozen while still hot, packed and stored at temperatures from -18°C to -20°C. They acquire their typical volume and shape already at the bakery, so working with them is quite simple.

On site, there is no need for a fermentation chamber for defrosting or final fermentation. When using an oven of appropriate power, it is even possible to bake them directly from the storage-freezer.

There is also no need for every day delivery of products to the site, since packed products can be stored in conventional freezers and low-temperature warehouses at -18°C, even up to 3 months, depending on the type of product. Thus, we are able to plan our stocks for peak production times.

On the market, there are also available packed, par-baked products, that are not frozen, but distributed chilled, at the fridge or even higher temperatures, of up to +20°C. The advantage of using the latter, is mainly in the lower costs of transportation and storage, although they have a significantly shorter shelf life. If not chilled, they can be stored for only a few days.

When choosing par-baked products for in-store baking, it is necessary to take into account the fact that baking on site, is practically a second baking or just a thermal regeneration. The products are further dried out, which can negatively affect the freshness, juiciness, texture… This may be an issue with wheat rolls, produced by fast, direct processes.

However, half-baked products are not necessarily a bad choice for in-store baking. They are interesting because they are easy to work with and can quickly fill the shelves during sales peak times. Furthermore, there are many products, that are usually offered for in-store baking only as par-baked. to skip a great amount of time and additional equipment for the necessary finalization on site. These products are, for example: ciabatta, larger and heavier pastries, as well as bread, burek, pizza… Nowadays, bakeries are able to produce top quality par-baked products using appropriate technological procedures:

- Preferment and sourdough technology

- Customized baking modes with minimal drying of products in ovens featuring good steam supply and forming of the proper crust to keep the moisture inside the product

- Fast freezing immediately after baking, using special cooling technique

- Smart process management, by using appropriate packaging materials, controlled deep freezers and strict application of cold chain technologies

2. Deep-frozen fermented products

Important advantage of deep-frozen and pre-fermented products is that the first baking actually happens on site. In ideal circumstances, when top quality products and appropriate oven are available, no special fermentation or defrosting cells are required on site. The products can be baked directly from the freezer.

Various small pastries, such as rolls, buns, mini strudels, puff pastry containing yeast and, of course, croissants, are available in this form.

To keep the quality of fermented, deep-frozen products, it is essential to apply cold chain technologies, without any deviations. The products ferment at the bakery up to 3/4 of the usual fermentation process, and the yeasts are still very active at that point. In order to stop the fermentation as soon as possible, the products must be cooled to -7°C within 30 minutes at most. At this temperature, the yeast ceases to act, and rapid cooling also contributes to the formation of smaller ice crystals that do not cause major damage to cellular structures. Frozen products are stored and transported at -18°C.

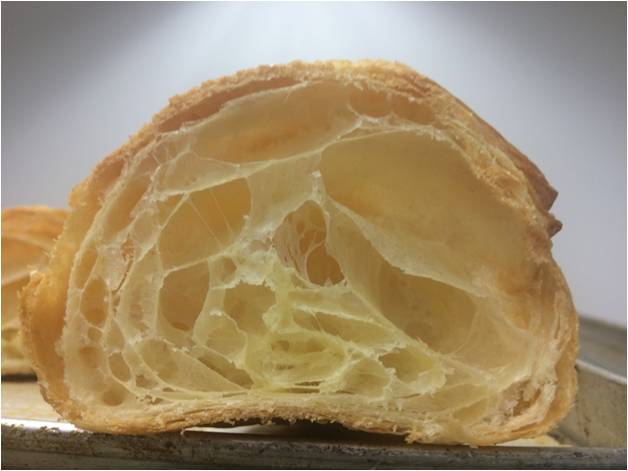

Uncontrolled temperature changes, negatively affect the shelf life and quality of the product. If the temperature rises above -7°C due to improper handling during transport and storage, the yeast activity resumes. This may result in products with a much smaller volume and inadequate structure. Let us keep in mind the products made of fermented puff pastry as well, where excessive temperature swinging during storage negatively affect the formation of the typical layered structure of baked products – if the products thaw during storage, the layers simply get stuck together.

If baking pre-fermented, deep-frozen products directly from the warehouse, without prior defrosting, we must be aware we will be putting dough with a core temperature of about -15°C in our oven. Therefore, the oven should work in such a way that the pastry first gets defrosted inside the oven, and only then the baking may begin.

During defrosting inside the oven, proper and sufficient supply of moisture is crucial. After the defrosting phase ends, the oven temperature must reach the operating baking temperature as soon as possible.

In theory, it is possible to manually control the process, the chief baker will carry it out without a hitch. For convenient and reliable baking of this product type on site, it is more appropriate to use a computer-controlled oven that automatically performs all stages of the baking process.

3. Deep frozen, not fermented products

There are two different kind of product:

Unfermented products, without yeast, that do not require proofing before baking; these include various products made of unleavened dough, like puff pastry, burek,… Working with frozen unleavened puff pastry products is quite simple, we bake them directly from the storage, without defrosting. Products such as burek, however, require some more time to defrost before baking. In this case, special defrosting chambers help keep the products from excessive drying in the air.

Yeast-containing products that have to be fermented before baking. These, so called green products. are deep-frozen at the bakery immediately after forming, or shortly after the start of fermentation. They are stored and distributed at -18°C.

Yeast-containing products need to be defrosted first, proofed and then baked. The procedure is time consuming and requires a lot of skill, time and a proper fermentation equipment. Ideally, the fermentation cell will have a built-in controlled defrosting and fermentation system, adjustable so that the products are defrosted and fermented just when we need them.

Such products are more suitable for baking on sites, wherever baking process is led by professional staff, like chefs and bakers are. Even though, the products are not completely made in their own kitchens or bakeries, they are able to add a personal touch to the products any time, using their knowledge and creativity.

Using specialized cooling technology for automatic defrosting and in-time fermentation, work is of course much easier and suitable even for the places, where special skilled stuff cannot be available all the time.